AFTERMARKET SERVICES

We offer

Liquid Ring Vacuum Pump/ Compressor/ Separator/Heat Exchanger Operations and Maintenance Service and Repair

Leave your equipment’s problem to the specialist while you focus on your core business! Our aim is to make your life easier

We at Laksel EPS Technologies with our 10+ years of experience of all types of pumps, compressor and separator systems, we provide trustworthy service and honest technical advice.

We offer quality equipment repairs, overhauls, on-site servicing and installation with our skilled technical staffs.

We also offer

The generation of vacuum and the compression of gases can be complicated and costly process. In many cases the fundamental process parameters are adjusted before the plant is started up, after which the settings are hardly ever modified. If however the system is left to itself for any length of time, problems can arise which will significantly reduce the availability of the plant and the efficiency of the system. A system which is not operating at the optimum level of efficiency therefore offers a considerable potential for savings. Optimizing it by improv¬ing its efficiency will lead to significant savings not only in energy but as a result, also costs. Moreover, environmental pollution and harmful emission will also be indirectly reduced.

We have an eye for a plant as a whole and an expert understanding of the finer points of machines and processes. Our comprehensive service package can optimize your vacuum and compressor system and support you with measures to improve plant availability and energy saving.

Analysis and evaluation

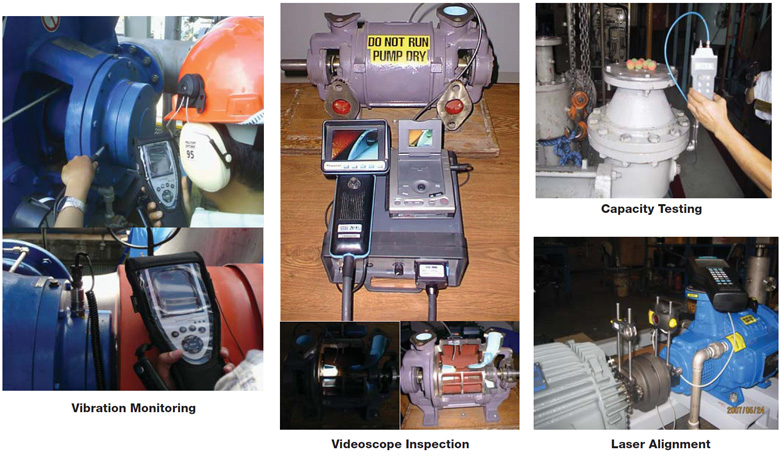

With our modern equipment, we will determine the parameters that

affect energy consumption and the efficiency of the plant. We will

check the shaft speed of the pump & compressor, calculate its

electricity consumption and establish its suction and flow rate at

predefined measuring points. Visual inspections of the pump &

compressor, both internal and external, complete the process of

assembling data. We also do separators revamping with internal

change & heat exchanger refurbishment. These are then evaluated,

revealing every point at which performance is less than the

optimum and at which improvements in efficiency can be made. With our modern equipment, we will determine the parameters that

affect energy consumption and the efficiency of the plant. We will

check the shaft speed of the pump & compressor, calculate its

electricity consumption and establish its suction and flow rate at

predefined measuring points. Visual inspections of the pump &

compressor, both internal and external, complete the process of

assembling data. We also do separators revamping with internal

change & heat exchanger refurbishment. These are then evaluated,

revealing every point at which performance is less than the

optimum and at which improvements in efficiency can be made.

Developing improvements and solutions

The results of our checks, combined with our comprehensive know-how, enable us to determine which settings should be adjusted to optimize your vacuum and compressor system, separation system and heat exchanger system even in complex processes. We will draw up a detailed test report and present the records and test data we have compiled to you. Our proposals for optimizing your system and energy saving measures will be based on this information.

Adaptation and system modification

When you decide in favor of one of our options, we will handle the required adaptation and modification of your system. In so doing, needless

to say, we will make provision not only for your specific requirements and process parameters but also any structural restrictions.

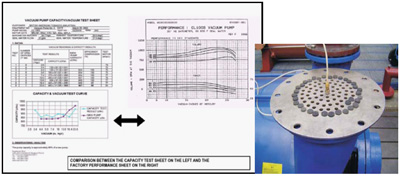

Capacity and performance checks:

precise measurements The flow rate can be determined by an specific method. By

using orifice plates, only a small gap between the vacuum

pump/compressor and feed pipe is needed for measuring

purposes.

As a result several pumps can be tested in the minimal time.

Our methods of checking flow rates ensure that the results are

accurate to within ± 5%.

To establish energy consumption, we check all the operating

parameters with calibrated test instruments.

The flow rate can be determined by an specific method. By

using orifice plates, only a small gap between the vacuum

pump/compressor and feed pipe is needed for measuring

purposes.

As a result several pumps can be tested in the minimal time.

Our methods of checking flow rates ensure that the results are

accurate to within ± 5%.

To establish energy consumption, we check all the operating

parameters with calibrated test instruments.

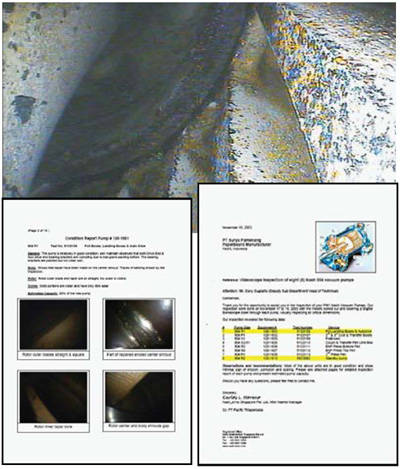

Fiberscope inspection By means of a fiberscope examination, the interior of the pump, the rotor, the

housing and the port plate/cones can be visually inspected. As a result, our

trained service personnel can not only identify damage to the pump, even at an

early stage, but also find any foreign objects inside. Contamination adversely

affecting efficiency and impermissible tolerances are thus identified and

eliminated in good time. We can spot signs of wear and determine the condition

of your pumps without dismantling the machine, then plan any repairs which may

be necessary before a failure occurs. Laksel EPS Technologies will carry out

fiberscope inspections while the plant is stopped or at any other time appropriate

to your operations.

By means of a fiberscope examination, the interior of the pump, the rotor, the

housing and the port plate/cones can be visually inspected. As a result, our

trained service personnel can not only identify damage to the pump, even at an

early stage, but also find any foreign objects inside. Contamination adversely

affecting efficiency and impermissible tolerances are thus identified and

eliminated in good time. We can spot signs of wear and determine the condition

of your pumps without dismantling the machine, then plan any repairs which may

be necessary before a failure occurs. Laksel EPS Technologies will carry out

fiberscope inspections while the plant is stopped or at any other time appropriate

to your operations.

Adaptation and system modification

When you decide in favor of one of our options, we will handle the required

adaptation and modification of your system. In so doing, needless to say, we will

make provision not only for your specific requirements and process parameters

but also any structural restrictions.

CFD analysis, repair and recommendation

CFD analysis, repair and recommendation of internal changes for existing separator,

tanks and separation system.

Other services

Laksel EPS Technologies offers a complete range of maintenance and repair services, either on site or at our Service Center, all repairs are

guaranteed. All new, reconditioned and repaired parts comply with the applicable specifications. Any technical improvements to individual parts

are automatically passed on to the customer. Regular planned maintenance will also help you with cost management.

Preventative actions minimize failures

Achieving the maximum degree of plant availability means preventing failures. Laksel EPS Technologies offers a comprehensive package of

measures to minimize this risk. In doing so, we work entirely in accordance with your time-table.

Inspections, maintenance and repairs Laksel EPS Technologies offers a complete range of services covering

maintenance, inspection and repairs, either on site or at our service centers, and

all from a single source. For these purposes, we have a comprehensive range of

machines at our disposal, all repairs are guaranteed. We use OEM spare parts

exclusively and all new, and repaired parts comply with the applicable

specifications. Any technical improvements to individual parts are automatically

passed on to the customer. Pumps are disassembled or inspected with a

fiberscope in order to locate the causes of faults, after which we let you know

why a pump has failed. Following a joint consultation, we can then introduce

further measures. If required alternatives can even be offered during repair work.

Laksel EPS Technologies offers a complete range of services covering

maintenance, inspection and repairs, either on site or at our service centers, and

all from a single source. For these purposes, we have a comprehensive range of

machines at our disposal, all repairs are guaranteed. We use OEM spare parts

exclusively and all new, and repaired parts comply with the applicable

specifications. Any technical improvements to individual parts are automatically

passed on to the customer. Pumps are disassembled or inspected with a

fiberscope in order to locate the causes of faults, after which we let you know

why a pump has failed. Following a joint consultation, we can then introduce

further measures. If required alternatives can even be offered during repair work.

Bearing condition monitoring

Specialists in the Laksel EPS Technologies collect data by monitoring the condition of the bearings in the machines you are using and evaluate

them in order to forewarn you of the need for early repairs before the machines fail. The monitoring process is carried out while the plant is

operating, eliminating any necessity for it to be shut down.

Service contract Regular, planned servicing will help you with cost management and

improve the efficiency of your vacuum pump or compressor. Laksel

EPS Technologies offers a service contract tailored to your needs

and embracing a comprehensive range of services, including:

Regular, planned servicing will help you with cost management and

improve the efficiency of your vacuum pump or compressor. Laksel

EPS Technologies offers a service contract tailored to your needs

and embracing a comprehensive range of services, including:

Plant inspection during operation:

- Visual inspection of the pump

- Checks on operating parameters such as suction capacity, bearing temperature, Shaft speed and energy consumption and a check on the condition of the bearings.

Inspection during downtime:

- Fiberscope examination or inspection through service openings.

- Flow rate measurement.

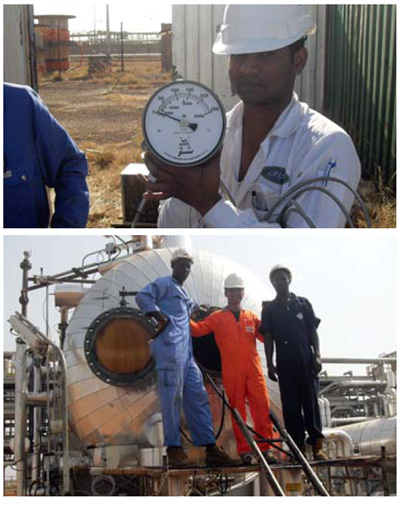

Installation, start-up assistance and trainingLaksel EPS Technologies will assist you in installing and setting up your vacuum/compressor system and, in so doing, help to reduce costly stoppage times. Our specialists have years of experience in complex systems of this type. We will check the installation and connections to the machines, start up the plant and adjust and check the process parameters. In addition, we will train your personnel.

Separators and Heat Exchangers

Our specialty equipments:

|